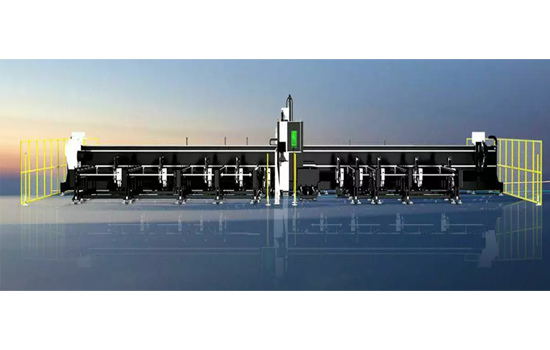

- PP-6036T3 is a side-mounted three-chuck heavy-duty laser pipe cutting machine. It is equipped with 360 square precision pneumatic 3-chucks, which can realize the zero-tailing cutting process (realized under the condition of reasonable process layout) and the largest single piece The bearing capacity of the pipe is 1200KG.

- Tube diameter cutting range: round tube φ30-φ360mm, square tube

□30X30-□350X350mm

- This pipe cutting machine is very suitable for cutting standard pipes such as round pipes, square pipes, and rectangular pipes, as well as profiles such as I-beams, channel steels, and angle steels. The third chuck is designed as a through-hole chuck, which can cut the whole pipe material and can clamp the pipe head in the shape of an inclined plane. The chuck is installed as a side-mounted installation, which effectively reduces the center height of the chuck, facilitates loading and unloading and improves the stability of the machine.

Advantages:

- Pneumatic chuck & Zero tailing material design

- Focus on processing heavy long tube workpieces

| PROFESSIONAL TUBE LASER CUTTING MACHINE | Model: PP-6036T3 | Brand: Philadelphia PRO |

| Pipe diameter range

(diameter of circumscribed circle) |

Φ30-360mm(Round tube)

□30X30-□350X350mm(Square tube) |

|

| Max single tube bearing | 1200KG | |

| X-axis travel | 425mm | |

| Y-axis travel | 6500mm | |

| Z-axis travel | 750mm | |

| Semi-automatic loading and unloading | Yes | |

| Maximum feeding length | 6500mm | |

| Maximum blanking length | 6500mm | |

| Maximum speed of chuck | 60 r/min | |

| Idle speed | 60m/min | |

| Acceleration | 0.5G | |

| Repeat positioning accuracy | ±0.03mm | |

| Voltage | 380V/50HZ | |

| Dimensions | L*W*H 18mx8.5mx3.6m | |

| Main Specification | |||

| No | Name | Quantity | Brand |

| 1. | Laser source | 1 set | Raycus/Max |

| 2. | Control system | 1 set | Cypcut FSCUT5000A |

| 3. | Laser cutting head | 1 set | Raytools |

| 4. | Servo motor | 5 | INOVANCE |

| 5. | Linear Guides | 6 | HIWIN |

| 6. | Rack and pinion | some | Taiwan APEX/YYC |

| 7. | Front and rear pneumatic chuck | 1 set | Philadelphia PRO |

| 8. | Water -cooler | 1 set | Hanli |

| 9. | Reducer | 4 | Motoreducer |

| 10. | Main pneumatic component | some | Taiwan AirTAC/Japan CKD |

| 11. | Main electrical component | some | CHNT |

| 12. | Automatic lubrication system | 1 set | Philadelphia PRO |

| 13. | Machine body | 1 set | Philadelphia PRO |

| Cypcut 5000A CNC system function | |||

| No | Name | No | Name |

| 1. | Tube deviation compensation | 15 | Control the action of the loading machine |

| 2. | Adaptive control of pipe surface height | 16 | Pipe floating support function |

| 3. | Fallback function | 17 | Floating unloading function |

| 4. | Breakpoint return | 18 | Inhalation function |

| 5. | Automatic edge patrol | 19 | Pipe surface profile correction |

| 6. | R angle cutting power, pulse trimming function | 20 | Cutting path display |

| 7. | Pulse perforation, two-stage perforation | 21 | Tube with film cutting |

| 8. | Power ramp | 22 | One-click alignment tube head function |

| 9. | Bend compensation function | 23 | One-click cut function |

| 10. | Elliptical tube alignment function | 24 | Maintenance module function |

| 11. | Fault self-test | 25 | Chuck avoidance function |

| 12. | Convert multiple cutting assist gas function | 26 | Cutting head avoidance function |

| 13. | Remote diagnosis function | 27 | Tube secondary clamping function |

| 14. | Leapfrog function | 28 | No looking up cutting function |